Say Good Bye To Rust

Recommended Current Price

JYOTI ZNCOAT TMT 550D

ViewHelpline Number : 97799-15000

Over the years, our products have undergone tremendous changes, and the objective of each change has been the same - to further better the quality of our products. We are a Quality-oriented organization and therefore, our focus is constantly on enhancing the durability, efficiency and functionality of our products. To complement our attitude is a work culture that allows innovation and creativity. The work culture is grounded in a value system that believes in fulfilling promises made to customers, channel partners, business associates, team members and stakeholders.

JYOTI the flagship brand of Madhav KRG Group, has been a pioneer when it comes to Innovation and Quality enhancement. Steel has always been an essential part of every foundation, and what better way to augment the foundation than to give a robust and long lasting TMT Bar.

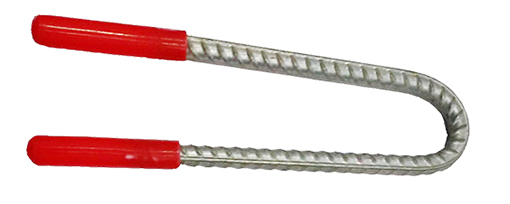

Presenting JYOTI ZINC COAT TMT Bars, with specialised Zinc Coating and manufactured for the First time in India by CGR Technology – Continuous Galvanising rebars. The Zinc coated TMT Bars are much superior and have a advanced life span, plus adding to the product appeal is a better product outlook and unique packaging.

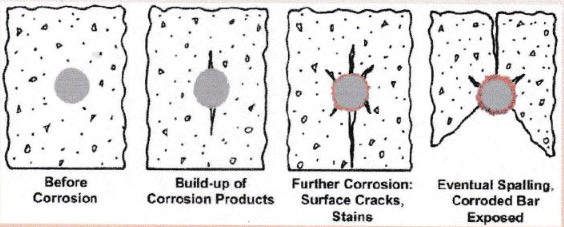

JYOTI ZINC Coat TMT bars are coated with Zinc and then surface passivation treatment is carried out on them. This induces a Protective layer onto the TMT Bar. Therefore the result is a double layered Final product thereby creating more life for the TMT bars inside a concrete environment.

Zinc provides unbeatable protection which is much advance than other coating options. Coating process is carried out by patented Continuous Galvanizing Rebars (CGR) providing optimal coating thickness, which makes certain a finer final product that is resistant to corrosion. The product has consistent & uniform coating thickness, with zero coating gaps in Final output.

Since the salt spray test is a standardized, most practiced and accepted corrosion test method as per ASTM B117-11, which is used to verify corrosion resistance of surface coating. Comparative salt spray testing (continuous exposure to 5% NaCI) of Jyoti ZINC Coat TMT bars and ordinary rebars showed that there was absolutely negative rust on Jyoti ZINC Coat TMT bars, and that too after 100 hours of exposure to the solution. Whereas the uncoated ordinary rebars developed a complete superficial red oxide layer just after a short exposure period of 20 hours.

Bridges

Specialized Structures

Buildings

Express Highways

Dams

Houses

of Galvanized Rebar in comparison with un coated TMT Rebars

more value to your buildings

Superior Corrosion Protection

Superior Corrosion Protection Unparalleled Bond Strength

Unparalleled Bond Strength Exceptional Life Cycle Cost

Exceptional Life Cycle Cost No Special Handling

No Special Handling Beauty that Lasts

Beauty that Lasts GSM - 350 (Minimum)

GSM - 350 (Minimum)