Say Good Bye To Rust

Recommended Current Price

JYOTI ZNCOAT TMT 550D

ViewHelpline Number : 97799-15000

Geologically, India is positioned at the northwestern end of the Indo-Australian plate which collides with the massive Eurasian plate. The process of one tectonic plate getting under another is called subduction, and the process has given India its unique topographical features such as the Himalayas.

While India’s positioning on the Indo-Australian tectonic plate and its tectonic evolution have gifted it a varied topography, they are also responsible for making the Indian subcontinent highly prone to seismic activity.

Seismic activity refers to the type, frequency and size of earthquakes that an area experiences over a duration of time. The main reason for the high number of earthquakes in India is that the Indian subcontinent is driving into Asia at the rate of 47 mm/year. A report co-published by the World Bank and the United Nations back in 2011 had estimated that 200 million city dwellers in India would be exposed to storms and earthquakes by 2050. In the last 10 years, India has experienced several devastating natural disasters such as Indian ocean earthquake and tsunami of 2004 and the 2005 Kashmir earthquake.

The Bureau of Indian Standards (BIS) has classified India into 4 seismic zones - II, III, IV, and V, based on the historical seismic activity in these regions. Zone V stands for highest seismic activity while Zone II stands for lowest seismic activity. Areas of Kashmir, Andaman and Nicobar Islands, Western and Central Himalayas, all states in the North-East and parts of North and Middle Bihar fall in Zone V. Delhi, Indo-Gangetic plains which include Northern Punjab, Chandigarh, Western Uttar Pradesh and Northern Bengal, and parts of Jammu and Kashmir, Himachal Pradesh and Uttarakhand come under Zone IV. Major cities of India such as Mumbai, Kolkata, Chennai and Bhubaneshwar are classified as Zone III.

Given the level of seismic activity across highly-populated regions of India, it would be a pragmatic measure to construct buildings that are earthquake resistant to prevent loss of life and property. However, construction in India more than often does not comply with standards established for earthquake resistance.

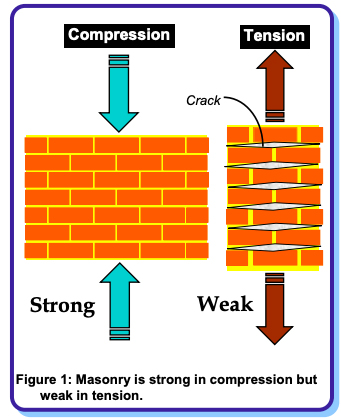

In India, non-urban constructions are often non-engineered consisting mainly of masonry of burnt and hardened clay bricks or stone and cement mortar. Sometimes, cement concrete - a proportioned mix of stone pieces called aggregate, sand, cement and water may also be used. In the poorer regions, mud mortar is used extensively. While buildings with such masonry, especially cement concrete, perform well under compression, they are unlikely to do well under tension.

Figure 1 - Compression vs Tension. Source - https://www.acchelp.in/pdf/student-case-studies-research-papers/EQTip09.pdf

To make buildings more earthquake resistant, it is important to give them strength under compression, as well as ductility which allows elongation of members under tension. Concrete cement is good for strength whereas steel offers ductility. The composite mix of steel reinforcement bars in construction is called reinforced cement concrete (RCC). RCC buildings primarily consist of vertical and horizontal members called beams and columns. The amount and positioning of steel in these members has to be optimal so that in the event of a failure of a member, it is because the steel bars have reached their highest level of strength in tension rather than the concrete reaching its strength in compression.

Figure 2 - Strong-column weak-beam design. Source - https://www.acchelp.in/pdf/student-case-studies-research-papers/EQTip09.pdf

For a strong, earthquake resistant building, it is important to ensure that a building’s columns are its strong link, created with the right composition of RCC. Seismic inertia forces dissipate through the floor and spread to the rest of the building, and when that happens, the collapse of a column can affect the entire building but the failure of a beam will cause a localized effect. Thus, columns need to be stronger than beams, as shown in Figure 2.