Say Good Bye To Rust

Recommended Current Price

JYOTI ZNCOAT TMT 550D

ViewHelpline Number : 97799-15000

Steel pipes and tubes have a large number of use cases across industries including construction. In construction too. Not only are they used in developing structures - from small storage units to skyscrapers, they are also used in making the tools that are needed to build these structures. They are sturdy, durable and highly customizable. Different steel alloys can be made by altering the content of carbon and adding other elements such as nickel, chromium, silicon, manganese, tungsten, molybdenum and vanadium.

Steel pipes and tubes are preferred because of their durability. They combine high strength with low weight, so they are ideal to use. They are capable of withstanding high heat and pressure, shock and vibrations. Under pressure, steel bends rather than break owing to its ductility, and this prevents spillage or leakage of materials inside the steel pipes and tubes. Steel, as a material, is also preferred owing to its corrosion resistant nature. While iron corrodes easily, steel can last for years without corroding. It is also a highly chemical-resistant material.

Steel pipes and tubes are also easy to create, customise and install. Steel, as a material is easy to work with and can be moulded into any shape. The diameters of steel pipes and tubes range from a few millimeters to meters, and they can be several kilometers long! They can even be modified to an extent on-site. Thus, it is easy to create customized pipes and tubes according to one’s requirements.

Another benefit of Steel pipes and tubes is that they are environment friendly. Steel can be recycled easily over and over again.

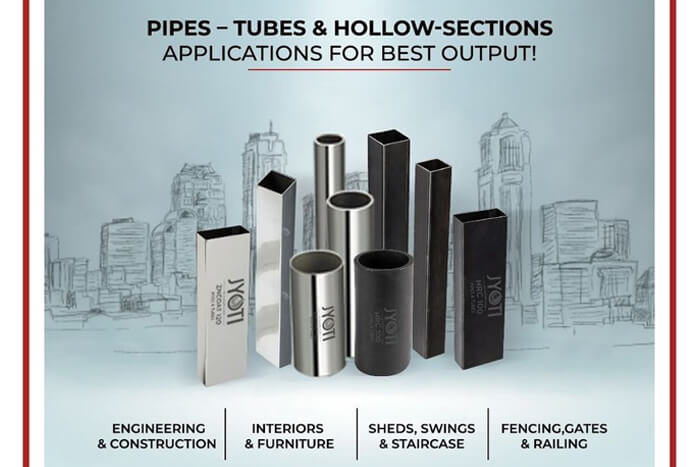

There are several applications of steel pipes and tubes in construction. Some of them are -