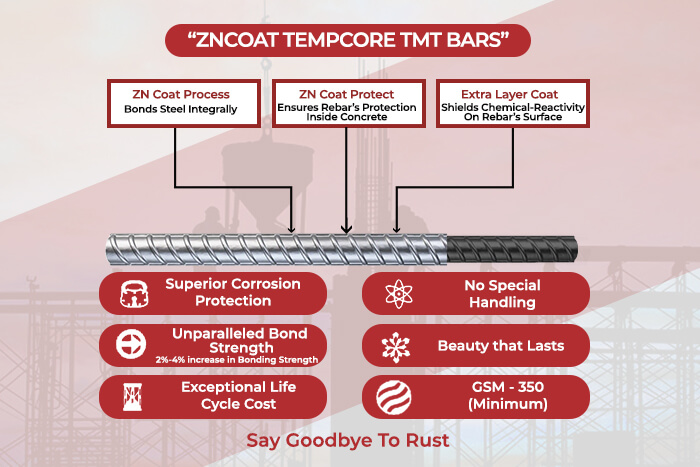

Say Good Bye To Rust

Recommended Current Price

JYOTI ZNCOAT TMT 550D

ViewHelpline Number : 97799-15000

Thermo mechanically treated (TMT) bars are used extensively in construction in India. They are used with concrete to give structural strength to buildings. But, TMT bars are made of steel, which means that they, like any other alloy of iron, are susceptible to corrosion. Corrosion happens when an alloy reacts with elements in the environment and gets oxidized. Oxidation, in the case of TMT bars, causes their surface to get damaged and thus reduces their strength. This, in turn, affects the strength and longevity of buildings.

However, TMT bars can be made corrosion resistant through certain techniques. Reputed TMT bar manufacturers in India follow a multi-step process for making TMT bars which includes quenching, self-tempering and annealing. In quenching, TMT bars that are fresh from the mill stand are rapidly cooled with jets of water. This process of cooling causes them to develop a hard outer layer called “martensite” which has excellent corrosion-resistant properties. In areas with high moisture content, TMT bars are also coated with Zinc coat make them more corrosion-resistant.

Madhav KRG Group will produce a new product, Continuously Galvanized Rebar (CGR). CGRs are value added rebars for higher life and low maintenance of infrastructure to provide significant cost savings compared to other corrosion resistant rebar systems. It offers on-site formability of the finished product, superior corrosion resistance in concrete at a price cheaper than other corrosion resistant rebar. The new CGR facility will further increase the usage of zinc in the steel industry and will support the much awaited need of supplying galvanized bars in the construction industry.

The major benefits of using corrosion-resistant TMT bars are as follows -